- Joined

- May 23, 2001

- Location

- Asteroid B-612

I am working on a project that has one particular requirement that is beyond my expertise.

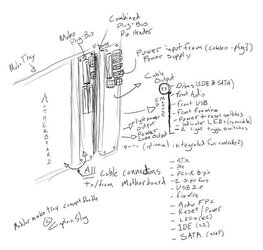

These pictures explain what I need fairly well

Essentially I will be needing two PCBs (2"x12" in size) that will act as a pass-through connector allowing all of the cables from the various parts of the machine to connect in a central location and then interface with the motherboard tray through a second PCB. The two will connect together (using typical sized pins used for motherboard headers) when the tray is inserted.

If there ends up being enough space left over an intergrated fan controller would also be extremely useful. Since the circuit is also extending the power/reset switches and LCD indication from the motherboard a front panel PCB may also be required (8" x 1" in size).

I am more than willing to pay for this to be designed and made and I would appreciate any thought, comments, questions, etc.

A theoretical requirement that I am not quite sure how to implement would be a locking mechanism that when the machine is powered-on will not allow the PCBs to be disconnected. I would love to hear any ideas on how to accomplish this.

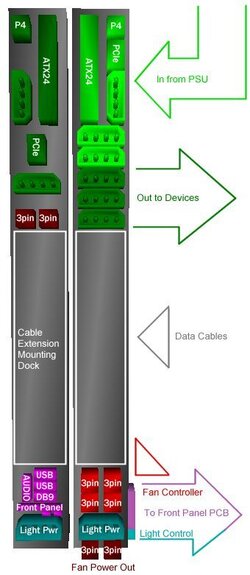

The upper section contains all of the power connectors and except for a few power traces to feed the light power output and fan controller it's an independent unit and can have it's own type of interconnect capable of handling the required current load. Whatever interconnect is used the pin requirement is only around 50 for this layout.

The middle section will just be a series of precisely positioned threaded mounting holes for attaching the flush-mount cable extensions (on the motherboard side) and the flush-mount rounded IDE and SATA cables (on the case side). This section will require custom cables, but no actual circuitry.

The lower section serves 3 functions.

1. Front-Panel extensions (Power/Reset, LEDs, USB2.0, Front Audio, 9-pin Serial header)

2. Light control (2 switches that toggle the 4-pin connectors)

3. Fan controller (on the Front-Panel PCB itself)

The front panel PCB will contain all the switches, ports, and fan controlling electronics. It can connect to the Plug-Bus with one or two cables. It's size limit is 8x2 inches.

The serial header extension is meant as a pass-through for an LCD unit. This could either be a header on the plug-bus, or an actual DB9 connector.

These pictures explain what I need fairly well

Essentially I will be needing two PCBs (2"x12" in size) that will act as a pass-through connector allowing all of the cables from the various parts of the machine to connect in a central location and then interface with the motherboard tray through a second PCB. The two will connect together (using typical sized pins used for motherboard headers) when the tray is inserted.

If there ends up being enough space left over an intergrated fan controller would also be extremely useful. Since the circuit is also extending the power/reset switches and LCD indication from the motherboard a front panel PCB may also be required (8" x 1" in size).

I am more than willing to pay for this to be designed and made and I would appreciate any thought, comments, questions, etc.

A theoretical requirement that I am not quite sure how to implement would be a locking mechanism that when the machine is powered-on will not allow the PCBs to be disconnected. I would love to hear any ideas on how to accomplish this.

The upper section contains all of the power connectors and except for a few power traces to feed the light power output and fan controller it's an independent unit and can have it's own type of interconnect capable of handling the required current load. Whatever interconnect is used the pin requirement is only around 50 for this layout.

The middle section will just be a series of precisely positioned threaded mounting holes for attaching the flush-mount cable extensions (on the motherboard side) and the flush-mount rounded IDE and SATA cables (on the case side). This section will require custom cables, but no actual circuitry.

The lower section serves 3 functions.

1. Front-Panel extensions (Power/Reset, LEDs, USB2.0, Front Audio, 9-pin Serial header)

2. Light control (2 switches that toggle the 4-pin connectors)

3. Fan controller (on the Front-Panel PCB itself)

The front panel PCB will contain all the switches, ports, and fan controlling electronics. It can connect to the Plug-Bus with one or two cables. It's size limit is 8x2 inches.

The serial header extension is meant as a pass-through for an LCD unit. This could either be a header on the plug-bus, or an actual DB9 connector.