- Joined

- Jun 5, 2003

- Location

- TEH INTERNETS

Last Updated: 7th June 05

Disclaimer: Neither www.overclockers.com or www.ocforums.com can be held responsible if you follow this guide or any other, attempt a volt mod, screw it up and subsequently fry your own hardware. Modification of hardware will definitely void any warranties on the product, so if you kill it, DON'T try to RMA it! Proceed at your own discretion.

Revision history:

2.6 - Link to source of post included, clarifying copying and redistribution

2.5 - Updated pic locations and added pencil mod

2.4 - Added pencil modding and updated cap mods

2.3 - Added capacitor mods

2.2 - Added index

2.1 - Added VREF and VTT information

2.0 - Re-wrote everything now in a new improved format with lots more info

1.4 - Fixed formatting, added some links, more info, added a buck converter pic

1.3 - Added stuff about current mode controllers

1.2 - Added stuff about VDDR on motherboards, and about low-power video card voltages

1.1 - Added stuff about finding voltages

1.0 - Initial version

Index of Sections

1.0 What is a volt mod?

1.1 The conventional volt mod: voltage controller theory

1.2 The conventional volt mod: feedback theory

1.3 The conventional volt mod: finding out what to mod

1.4 The conventional volt mod: the tools

1.5 The conventional volt mod: performing the mod

1.6 Pencil Volt Modding

2.0 Current sensing - the roots of the droop mod

2.1 The P4C800 droop mod

3.0 Overcurrent protection mods

4.0 VTT, VREF and other wierd voltages

4.1 VTT, VREF and VTT=VREF mods

5.0 Capacitor mods

1.0 What is a volt mod?

A volt mod is a method of increasing the supply voltage to a chip or chips using methods other than BIOS, driver hacks or pin mods. Typically this involves soldering a fixed or variable resistor to a certain location on the PCB near to where the controller chip for that particular voltage resides. With conventional volt mods decreasing the resistance increases the voltage out and the next section will tell you why.

Other mods are covered in this guide such as VTT/VREF stabilisation mods, droop mods, overcurrent trip mods and overvoltage mods.

1.1 The conventional volt mod: voltage controller theory (not essential, but if you want to know what all the coils 'n stuff does, read on)

Almost all important supply voltages these days are controlled by switch-mode DC-DC converters. These are essentially 2 MOSFETs, an inductor, diode and capacitor with a control circuit in the form of a small chip. The output voltage is fed back into the control chip to keep it stable. Switching regulators can provide large amounts of current at low voltage and are highly efficient in design (specific designs for exact voltages can approach 95% efficiency) and are therefore ideal for microprocessors or high-speed RAM. The control chip sends out a variable pulse wave that turn on and off the "top" and "bottom" MOSFETs in sequence. This causes a ramp up and down in the inductor's current and this efficiently converts a supply-level (+5V, +12V, +3.3V) voltage into a lower more local one for use by a chip.

This diagram should help you understand what is going on, but knowledge of the method of energy transfer isn't that important in typical volt-modding scenarios. For a more in-depth look at the physical and mathematical aspect of what's going on, check out www.smpstech.com

Most modern voltage controller units are small, self-contained controllers that switch two MOSFETs and usually only require a few external resistors and capacitors to set their oscillating frequency and output voltage level. They have a reference voltage which the feedback voltage is compared to to provide the correct switching waveform to the MOSFETs. The simplicity of volt modding comes from the fact that the output voltage is fed into a potential divider (2 resistors with a set ratio of values) such that the output of the divider is exactly equal to the reference voltage inside the IC.

However it may not be as simple as that for voltages that need to handle a lot of current draw. It is possible to make a chip that outputs "on" signals to pairs of MOSFETs/inductors in step, called phases. This is accomplished by modifying the triangle wave generator present inside every PWM control chip to output n waves each with a 360°/n phase shift, and add n lots of PWM control circuitry along with it. CPU voltage regulators often have 6 MOSFETs and 3 inductors near the socket - each of those pairs is switching on in accordance with a wave that is 120° out of phase with the other. This has the effect of

It doesn't stop there. Gigabyte sometimes put an expansion slot for an additional power module to give "6-phase power" - what this actually does is daisy-chain another 3-phase regulator onto the one on the motherboard. A control signal is put to the module from the core voltage chip that synchronises the whole lot. This normally isn't necessary, with most manufacturers opting for 3-phase systems on most Athlon64 and Pentium4 (even Prescott-worthy) motherboards. Some 4-phase regulators are starting to hit the market though.

VID inputs are common on CPU VCORE regulators, as this allows the CPU to set it's own specific voltage (which can be overridden by the BIOS). In controller chips that have VID inputs the digital signals are converted into a variable reference voltage by means of a precision digital to analogue converter (DAC). The rest of the control circuitry is exactly the same as a non-VID chip, and volt modding these is carried out in the same fashion 99% of the time.

1.2 The conventional volt mod: feedback theory

Fortunately for us however complex the control chip, they almost always leave a simple potential divider with the job of taking the output voltage and feeding it back into the chip. The chip has an internal precisely-calibrated reference voltage that the error amplifier inside the chip compares the stepped-down output voltage to. If the voltage is too high, it reduces the duty cycle. Too low and it increases it. What a volt mod does is trick the chip into thinking the output voltage is too low and so boosts it.

The typical potential divider circuit is like this:

and the output voltage in DC terms can be expressed as a function of the two resistors and the reference voltage:

Now this means we can increase Vout by decreasing R2. This happens because the chip wants to keep the Vref voltage constant and equal to it's own internal reference voltage. Decreasing R2 = more voltage dropped across R1 and so Vout needs to be higher to keep Vref at whatever the internal voltage is. The equation for the voltage after the mod is thus:

What does this mean? Fortunately for us R2 is the resistor between the feedback pin of the IC and ground, so it is simple to fix a resistor permanently or semi-permanently to the board; just solder the resistor to the legs of the IC corresponding to ground and FB, or alternatively use a Surface Mount Grabber/Pomona Grabber to have a removable mod. Many people prefer the variable "how fast do you want to go today?" mod, or use jumpers between the resistor and IC leg to enable/disable the voltage boost.

1.3 The conventional volt mod - finding out what to mod

What pins are FB and Ground? And what if there is more than one voltage controller chip?! What's the voltage?!?!?!?!

To find out the FB and Ground pins you need the datasheet for your chip. There should be some numbers on the top of the chip, enter these into Google. If you have two numbers then one will be a serial number and the other a part number. One will yield results, the other will not. Enter the part number into Google and if you get a PDF link, follow it. The description should contain some or all of these key words:

Buck PWM Voltage Controller DC-DC

If you get "dual MOSFET" or something then the "chip" is actually two switching MOSFETs that the voltage controller drives. These are commonly used on low-power regulators instead of the larger "standard" 3-leg MOSFETs.

Some companies do not let Google crawl their site directly so you don't get Google hits for the PDF file, but they do release their datasheets to a database. A good one to use is www.doom.com which requires you to pay to view the sheets from the site, but will look up stuff for free. Enter the part number and find out who the manufacturer is from the results. Then go to the manufacturer's site to get the datasheet.

Since most volt mods are for video cards, here are some vid-card specific guidelines..

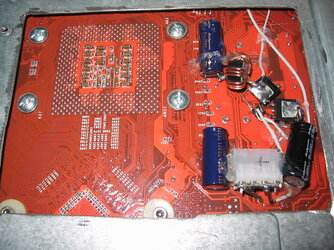

Many video cards do have more than one controller chip however, and you need to enter the part number of every little chip on the board with 8 pins or more. They shouldn't be too numerous, but check both sides of the card. I haven't seen a vid card yet that has the control circuitry on the underside as the large smoothing capacitors need to be mounted as close as possible to the switching circuit, so they are often put on the opposite side of the board as close as possible to the chip. Putting large caps on the top of the board is almost unheard of due to form factor specifications.

These multiple chips on a video card will control different voltages. Typically there are 3, VDDR, VDDQ and VGPU. You can only tell which is which by measuring the voltage across caps near the chip/MOSFETs. Put a voltmeter across the exposed capacitor leads (if you don't feel like frying your card, put heatshrink or a thin strip of duct tape on the test probe so that only a tiny bit of metal is exposed, to prevent accidents). Record all the voltages and what chip they are close to.

VGPU is most likely in the range of 1.2-1.8V, VDDR 2.5-2.8V, VDDQ is definitely going to be less than DDR, but can be very close to it. You measure the voltage at multiple points by putting a voltmeter across the large electrolytic capacitors with legs that stick through the board. Voltages are easy to find on video cards. Caps on the underside have their legs poking up through the PCB, so you can stick a multimeter on them to measure the voltages. Important voltages that have a lot of current draw typically have lots of electrolytic caps between it and ground.. If you have only surface-mount capacitors on your card, or if you are working on a motherboard then you will need to find an alternative place to measure if you have shaky hands. You can try an inductor leg that is the furthest away from the MOSFETs compared to ground, for example.

With my 9600XT I got these voltages when probing around with my multimeter.

http://premium.uploadit.org/L337M33P/Voltmodguide/9600XT-Voltages2.PNG

http://premium.uploadit.org/L337M33P/Voltmodguide/9600XT-Voltages.PNG

Voltage regulator chips on a motherboard are going to be trickier. There are many more chips on a motherboard, not all of them standard sizes either. Still, the same principle applies. Put all the part numbers in and see what comes out. Finding the CPU core voltage regulator should be easy, it's usually a large chip as it has a built-in 5- or 6-bit DAC to convert the CPU VID pin data to a voltage. Finding the DDR and chipset voltages and their respective controllers will be hard as the chips are often buried amongst other components. The legs of the caps are on the other side of the motherboard, so you need an alternative point to look for. Don't use MOSFET legs as they will typically have a) 0V b) a switching waveform (which you will ground through the capacitance in the multimeter) c) a voltage that is close to, but is not, the right voltage.

Here are some examples of what to look for:

VDD Chips on an A7N8X

VDDR chips on an A7N8X

The best place to look is the legs of inductors. The leg of the inductor on the side of the capacitors (the other side will be connected to one or two MOSFETs) should have the right voltage on it. If you have a pomona grabber or really small probe clip then it should easily fit around the leg.

1.4 The conventional volt mod - the tools

You will need (i.e. don't attempt a mod without):

Digital Volt Meter

Be sure to know how to use it properly. They are inexpensive, places like RadioShack sell them. You need crocodile clip ended test leads as well as the pointy types.

Variable Resistors

A selection of 10-turn or multiple turn high-precision potentiometers. You need values above 10K, but less than 100K. Most feedback (R2) resistors are in the range 100-200 ohms.

Pomona grabbers

The easiest way to clip a lead on to a surface mount chip. They have two little wire clips that come out when you press the button in and are spring-loaded.

Linky

Soldering kit

Soldering is the key to making a permanent and successful volt mod. If you aren't at least moderately competent with a soldering iron, don't break it out on a $200 video card. If you do know what you are doing, a medium-power iron is all you need for surface mount work, and the tip size is far more important. Use a 1mm point tip or less, and make sure it can be well tinned as you will find that applying solder wire will just create huge blobs on the joint. Tin the bit then use the small amount of solder to stick the chip leg and lead together. For soldering caps/resistors/other random chips to the PCB in pursuit of a mod, I find that a selection of fine tweezers, needles and cocktail sticks is ideal for nudging the tiny components into place.

Wire

If you are using a variable resistor then it's advisable to run a short length of wire (no more than 10cm) to enable you to mount the VR at the edge of the PCB/clear of surrounding components. Short lengths of wire are preferable because a long run can increase the risk of snagging it and ripping the wire off, and longer wires act as radio-frequency aerials capable of picking up more noise than they would if they were short. Solid core wire is the best to use since it allows accurate soldering without it going everywhere. Heatshrink-wrap the connections to the VR if you must.

Glue of the hot glue gun sort

Secure your volt mod. Glue the resistor body or the VR's plastic case to a bare bit of PCB. It allows easier access to the VR and prevents any solder connections from breaking off. If you keep the joint to the chip low-profile then you needn't worry about the leads being broken off.

1.5 The conventional volt mod - performing the mod

With the hardware off/computer off, measure the resistance between the feedback pin and ground. Put the -ve lead on the ground and +ve on FB to avoid reverse-biasing any circuitry inside the chip. The resistance should be under 1K and moderately steady. Therefore if the resistance is 1K putting a 1K resistor in parallel with it will halve the resistance and double the output voltage, which you don't want - you at most want a 20% increase. This is why you start with a high-value variable resistor and slowly lower it to get the desired hike in voltage. Then you unclip it and measure the resistance.

Adjust the resistor to max (max resistance between middle pin and an end pin) and solder two wires to these pins. Put the pomona grabbers on these wires.

Don't attach or remove the grabbers/leads while the piece of hardware is on! If you short out a leg then stuff will fry!

Using crocodile clips or similar, attach the voltmeter to the voltage measuring point, e.g. a capacitor that you know has the GPU voltage across it. Record the voltage. If you are doing a mod to a motherboard then you still need a voltage measurment point, NOT hardware monitoring. Only use hardware monitors to confirm your readings. Don't do a mod if you don't know where to stick the voltmeter!

Pin 1 is designated by a mark on the top of the chip - a dot or chamfer on the case, or if the top end has a dent in it or is entirely shaded then Pin 1 is the left hand pin closest to the shaded area, with the shaded area at the top.

CAREFULLY attach the grabbers to the FB and Ground pins. Power on. The voltage should go up from the previous voltage by a tiny fraction. If no change is detected wind the pot SLOWLY to lower the resistance. If no change happens by the first turn then you screwed up, power off and take the pomona grabbers off pronto. Recheck the datasheet, and if you were right then you may be altering another voltage. Check each of the different voltages that you got across the capacitors and put the grabbers back on with the pot set to full resistance again. If you still don't get a change then you are doing something wrong, ask in this forum for assistance.

If you don't get a decent boost in speed from the volt mod then take it off as it's doing no good to the chip. If it is successful then congratulations, and post how you did it!

1.6 Pencil Volt Modding

This is a cheap and dirty method of quickly increasing the voltage from most regulators - I would NOT recommend it for CPU voltage hikes as they are prone to being highly variable.

The basis of the pencil volt mod is that graphite is conductive. In fact 2B/4B pencils conduct more than hard ones because they have less clay in the leads. For pencil modding you want a 2B pencil. An additional current path is formed around one of the feedback resistors by simply drawing or scribbling a line along the side of it.

To find out what to mod, the method is nearly the same as the conventional mod except that you have to carry out one more step: find the feedback resistor that connects FB and ground. I suggest you try to follow the PCB tracks first, and if the suspected resistor has the same value of resistance as what you measured at FB/GND then it's the right one.

I HIGHLY recommend that you monitor the resistance change with a multimeter as you are pencilling the resistor. To lower the resistance just rub the pencil down the side of the resistor between the two solder caps. You should be able to get a modest reduction in resistance, of the order 10%. Use the "new voltage" formula to find out what the modded voltage will be from the new resistance between FB and GND. To reduce the resistance just stick a cotton bud in there and wipe it off. Do NOT let the pencil dust get under BGA chips or between pins. That is a Bad Thing™

I have performed this mod myself and know first-hand that it can produce very variable results. Breathing on the resistor increased the voltage due to the moisture on the graphite! Therefore I do not recommend that this be a permanent mod.

2.0 Current sensing - the roots of the droop mod

As most of the droop mods performed seem to be on the Asus P4C800/-e model, I will cover what is involved when you mod that particular board. More generally though, a droop mod does this:

Inside most modern CPU Vcore regulators there is an additional feedback loop that modifies the output waveform depending on the load placed upon the system. This method of control uses current sensing and can provide several useful features in only one additional feedback loop.

Current sensing can be achieved one of three ways

Current sensing is useful because it allows a droop function (or "Active Voltage Positioning") to be implemented along with load balancing (putting more current through one meatier phase or making sure the currents are equal in all) and allows for overcurrent protection methods.

The droop function means that the output voltage drops linearly with load, reducing the effect that transient current surges have on the output voltage and allowing the manufacturer to use fewer capacitors. This datasheet excerpt puts it across quite well:

Performing a droop mod on a Vcore regulator often involves soldering another resistor to the circuit lowering the gain of the current summing amplifier. It most likely will be different for different converters so it is essential that you find the datasheet, know how it works and know what a ballpark resistance should be before attempting a mod.

2.1 The P4C800 droop mod

The droop mod for the P4C800 serves to reduce the Vcore voltage drop under load. Asus have left off several capacitors and the secondary low-side MOSFET for each phase and as a result increased the droop strength to compensate for their cost-cutting. This, while fine in principle, does not sit well with overclocking which increases the current draw beyond that of what is normal, and consequently the output voltage droops too much resulting in an unacceptable difference between idle and load.

The control chip used is the ADP3180 from Analog Devices. It has 3 functions derived from sensing the current in the inductors - overcurrent protection, droop function and current load balancing. The one we are interested in is the summing amplifier that is connected across each of the inductors.

On page 13 there is a diagram of the droop circuitry, CSSUM and CSCOMP etc. These pins and the surrounding resistors form an inverting summing amplifier that measures the average current being drawn by the processor using the inductors' DC resistances. The voltage drop is averaged because of that phat capacitor and associated resistor forming an RC network that reduces the gain of the system at high frequencies.

What happens when you droop mod it is you solder a resistor (28K) directly in parallel with the cap. This decreases the gain of the circuit (and increases the rolloff frequency, an added bonus as the circuit responds quicker) and thus from equation (6) the "DC resistance" of the whole converter is less. This makes the voltage slope (VCORE versus Iout) less so there is LESS voltage difference between idle and load, and less droop under heavy load. This will compromise the output ripple voltage slightly when a high-current transient is put on the circuit, but it is still within normal parameters.

The droop function was also designed to allow the incorporation of a temperature-sensing thermistor in the circuit. This was to allow the circuit to respond to the change in resistance of the inductors with temperature - copper increases in resistance with increasing temperature so if a thermistor is put close to the inductor then the circuit can be further compensated to adjust the droop with temperature. For most purposes a simple reduction in droop is sufficient.

3.0 Overcurrent protection mods

Undertaken by the more extreme overclockers, an overcurrent protection mod increases the current limit threshold of the controller. When a core voltage controller experiences a heavy current draw it can trip and operate in "hiccup" mode. In this mode it essentially turns off and occasionally tries to turn the output voltage back on to test if the overcurrent condition is still present. This prevents damage to the MOSFETs and PCB in case of a short. When doing some nuclear-powered overclocking and volt modding, past a certain increase in clock speed or core voltage may cause the whole thing to crash unexpectedly or give a blank screen. This is the overcurrent kicking in and turning off the core voltage, with obvious consequences.

Overcurrent protection is accomplished mostly 2 ways. As core voltage controllers rarely use the series current sense resistor anymore, the voltage drop across the upper MOSFET is most often used for things like graphics cards, and the current in the inductor is used in things like the ADP3180. In the case of the MOSFET-sensing chip, there is a resistor between the supply voltage and a pin, which acts as a fixed current sink. This creates a constant voltage drop according to V=IR, and this dropped voltage is compared to the drop across the MOSFET when the MOSFET is switched on. This result is then averaged and fed into a comparator. If the voltage drop across the MOSFET becomes greater than the drop across the resistor then the circuit triggers the hiccup-mode operation.

It follows that increasing the resistance between the current sink pin and the supply voltage increases the drop across the resistor and thus increases the threshold voltage drop across the MOSFET. This in turn can allow more current to pass without tripping the overcurrent protection.

With the inductor-sense method and multiple phases it can be much more difficult to do it successfully unless there is a dedicated pin and current limit setting resistor.

A mod with the MOSFET method is simple - desolder the resistor and replace it with a higher value. Alternatively you could connect a 1K pot to one of the resistor's ends and solder it back on, so you can't go below the standard overcurrent protection, only increase it.

These mods require a little more forethought and understanding than your average volt mod, and you need to do the following diagnostics before attempting one:

4.0 VTT, VREF and other weird voltages

DDR SDRAM is a memory technology used on almost all host CPU and many mid and low-end graphics cards. It is a requirement of the DDR signalling interface, SSTL-2 (Stub Series Termination Logic) to have a bus termination voltage, VTT, and an internal reference voltage, VREF.

VTT

Data buses are terminated at the ends by a resistor connected to another voltage, usually ½ the signal amplitude voltage. This serves the purpose of preventing signal “reflections" which would otherwise happen if the data/address wires just stopped at the end of the run. I can't be bothered to come up with an analogy so here’s one courtesy of Google:

For more back-story and JEDEC specifications see this application note.

Each signal wire is run to a resistor and the other end of the resistor connects to the common VTT rail.

A passive termination would just mean that the resistor of similar resistance to the trace gets connected to ground, but all motherboards and graphics cards employ active termination. Active termination means that a) there is a termination voltage and b) this voltage is regulated.

It is a requirement of the regulator to be able to both source and sink current to keep VTT at a fixed value. These regulators can be switched or linear, and the choice is usually down to how many chips are going to be hanging off the bus/how fast it goes. Switched regulators can typically source and sink much more current than linear ones, but are complicated and more costly, so linear ones are most often used.

Examples:

My 9600XT’s bus termination regulator and datasheet

Abit NF7-S termination regulator datasheet

As you can see from the datasheet of the motherboard termination regulator several features have been lumped into one chip. Primarily the ACPI suspend-to-RAM feature needs to be supported by the various memory voltage regulators, and this needs a connection to +5VSB as well as the chipset to work. Other features like Power_GOOD outputs and digital voltage increase pins are often implemented.

A word on VREF

VREF is another voltage supplied to the memory chips in addition to VDDQ and VDDR. It is meant to be ½ of VDDQ to within a few percent, and serves to provide a reference (surprise surprise) to the receiving circuitry. If the voltage on the bus is > VREF then a “1” is passed to the internal circuitry, if it is < VREF then a “0" is passed along. While this may sound trivial and unecessary consider that the DDR bus is operating at 200+MHz with about 2.5V signal swing. Any small amount of high-frequency noise such as caused by another data bus nearby will cause jitters and noise in the adjacent bus. Adding a reference voltage means you can use comparators to clean out the garbage.

For more information, diagrams of the equivalent circuits and notes on the SSTL-2 interface see this PowerPoint presentation. It even has oscilloscope graphs of the DDR bus voltages.

As the voltage references on such chips are rarely the result of a potential divider this can cause problems if you bump up VDDR by volt-modding the VDDR controller – the VTT regulator chip still thinks that the voltage is at a set 2.7 or 2.6V and fails to increase VTT to compensate.

4.1 VTT, VREF and VTT=VREF mods

As touched on above, a VREF or VTT mod serves to increase stability rather than increase performance. As specified on most DDR SDRAM product datasheets, VREF and VTT should fall within a very narrow margin centred on 1/2 of VDDQ.

E.g. from Samsung's popular graphics card RAM datasheet:

(Page 10, DC operating conditions)

VREF

Min: 0.49*VDDQ

Max: 0.51*VDDQ

VTT

Min: VREF-0.04V

Max: VREF+0.04V

As you can see these are narrow operating regions, so when overclocking having a precisely-tuned VREF and VTT setup can increase your overclocking headroom. Normally the RAM voltage controllers will output a reference and termination voltage that is exactly half of VDDQ, but when you start doing VDIMM volt mods and VDDQ volt mods the VREF and VTT voltages can start to go out of whack. This seldom occurs on boards where you just mod VDIMM because VDDQ is (mostly) independent, but when you are going for flat-out speed with a DIMM voltage in excess of 3.3V and the whole entourage of mods, a correction to VREF and VTT may be necessary.

Most VREF/VTT chips employ direct feedback, which means that there are no potential dividers we can stick a resistor across to alter the voltage. For mods to boards such as the IC7-G and NF7-S you are in effect replacing the wire with a small-value potential divider which you CAN adjust. The reason values much smaller than the ordinary volt mods is because the chip may take a small current when measuring VTT/VREF and this will affect the voltage produced by the potential divider because it relies on very little current being drawn off it with respect to the current flowing through it.

These mods often require putting a resistor in the current path from the voltage rail to the chip, so this is why you have to cut traces on the motherboard. You bypass the cut with the resistor you solder to the board.

For tracking circuits, this essentially produces a voltage boost to the feedback when Vdimm goes above a certain value. This kicks the chip up the rear end and makes it output a higher voltage than it would normally if you just increased Vdimm. The circuits are usually specific to each motherboard due to variations in current, gain and severity of VTT tracking loss.

5.0 Capacitor Mods

Capacitor modding, or more usually abbreviated to capmodding, is the process of adding or otherwise altering the bulk decoupling capacitors on motherboards/graphics cards. The usual cap mod on a graphics card is to add extra capacitors in parallel with the ones already there but on the topside of the board. For motherboards it's a little more complicated as sticking them on the back means you have to cut motherboard trays and such.

The aim of the mod is to reduce the ripple voltage that the switching regulator produces. As the inductor and capacitors are driven by a PWM waveform you will get some small ripple voltage due to the change in current in the inductor. Most switching regulators used on motherboards are synchronous and operate in the continuous mode (i.e. the inductor current never drops to zero) which reduces ripple somewhat, but doesn't eliminate it. Typical values are 50mV peak to peak.

Sticking extra capacitors on increases the charge storage capacity of the whole converter for a given voltage. Translated that means more charge can be drained from the capacitors for the same level of voltage drop, or conversely less voltage drop for a given transfer of charge. This is A Good Thing™, since when pushing the envelope on phase-change cooling you are going to be drawing some hefty amperes and need more storage capacity to compensate.

Another side-effect of adding more capacitors is that it reduces the ESR of the bulk decoupling circuit - capacitors aren't perfect and have an equivalent series resistance that can be measured by how much current the capacitor can dump at any one time. Think of it as a bucket with a hose attached to a hole in the bottom. How fast you can get the water out depends on the width of the pipe and the level of water in the bucket. The constant of proportionality is the ESR.

ESR behaves like any normal resistance and so sticking capacitors in parallel reduces the overall ESR according to the parallel resistors rule. This increases the transient current availability of the converter (such as when you suddenly hammer the CPU with Prime95) and reduces the dip in voltage that happens at the instant of increased current.

While this may all sound like a perfect solution to juddery rails there are several caveats:

Adding different brands and ratings of capacitors means that the ESR is no longer constant per capacitor. The switching regulator has a carefully calculated zero in it's frequency response at the self-resonant frequency of the inductor-capacitor-ESR circuit and a pole at the break frequency of the ESR-C pair, to avoid oscillation. These are given by

Source

I would only recommend adding the same type of capacitor in parallel with the ones already in place because if C and ESR is kept constant for each capacitor, the second equation is unchanged, and FLC decreases, which has negligible impact up to a point.

This is my extrapolation of what to expect from cap modding, so I give it a massive health and safety warning, but other people have had a number of successes with any old capacitors that have a high enough voltage rating and approximately the right capacitance. Ideally you want to be looking at the supply voltage with an oscilloscope before sticking extra bulk capacitors on though.

Article source text: http://premium1.uploadit.org/L337M33P/Voltmodguide/VoltModGuide.txt

© 2005. NO rights reserved.

Disclaimer: Neither www.overclockers.com or www.ocforums.com can be held responsible if you follow this guide or any other, attempt a volt mod, screw it up and subsequently fry your own hardware. Modification of hardware will definitely void any warranties on the product, so if you kill it, DON'T try to RMA it! Proceed at your own discretion.

Revision history:

2.6 - Link to source of post included, clarifying copying and redistribution

2.5 - Updated pic locations and added pencil mod

2.4 - Added pencil modding and updated cap mods

2.3 - Added capacitor mods

2.2 - Added index

2.1 - Added VREF and VTT information

2.0 - Re-wrote everything now in a new improved format with lots more info

1.4 - Fixed formatting, added some links, more info, added a buck converter pic

1.3 - Added stuff about current mode controllers

1.2 - Added stuff about VDDR on motherboards, and about low-power video card voltages

1.1 - Added stuff about finding voltages

1.0 - Initial version

Index of Sections

1.0 What is a volt mod?

1.1 The conventional volt mod: voltage controller theory

1.2 The conventional volt mod: feedback theory

1.3 The conventional volt mod: finding out what to mod

1.4 The conventional volt mod: the tools

1.5 The conventional volt mod: performing the mod

1.6 Pencil Volt Modding

2.0 Current sensing - the roots of the droop mod

2.1 The P4C800 droop mod

3.0 Overcurrent protection mods

4.0 VTT, VREF and other wierd voltages

4.1 VTT, VREF and VTT=VREF mods

5.0 Capacitor mods

1.0 What is a volt mod?

A volt mod is a method of increasing the supply voltage to a chip or chips using methods other than BIOS, driver hacks or pin mods. Typically this involves soldering a fixed or variable resistor to a certain location on the PCB near to where the controller chip for that particular voltage resides. With conventional volt mods decreasing the resistance increases the voltage out and the next section will tell you why.

Other mods are covered in this guide such as VTT/VREF stabilisation mods, droop mods, overcurrent trip mods and overvoltage mods.

1.1 The conventional volt mod: voltage controller theory (not essential, but if you want to know what all the coils 'n stuff does, read on)

Almost all important supply voltages these days are controlled by switch-mode DC-DC converters. These are essentially 2 MOSFETs, an inductor, diode and capacitor with a control circuit in the form of a small chip. The output voltage is fed back into the control chip to keep it stable. Switching regulators can provide large amounts of current at low voltage and are highly efficient in design (specific designs for exact voltages can approach 95% efficiency) and are therefore ideal for microprocessors or high-speed RAM. The control chip sends out a variable pulse wave that turn on and off the "top" and "bottom" MOSFETs in sequence. This causes a ramp up and down in the inductor's current and this efficiently converts a supply-level (+5V, +12V, +3.3V) voltage into a lower more local one for use by a chip.

This diagram should help you understand what is going on, but knowledge of the method of energy transfer isn't that important in typical volt-modding scenarios. For a more in-depth look at the physical and mathematical aspect of what's going on, check out www.smpstech.com

Most modern voltage controller units are small, self-contained controllers that switch two MOSFETs and usually only require a few external resistors and capacitors to set their oscillating frequency and output voltage level. They have a reference voltage which the feedback voltage is compared to to provide the correct switching waveform to the MOSFETs. The simplicity of volt modding comes from the fact that the output voltage is fed into a potential divider (2 resistors with a set ratio of values) such that the output of the divider is exactly equal to the reference voltage inside the IC.

However it may not be as simple as that for voltages that need to handle a lot of current draw. It is possible to make a chip that outputs "on" signals to pairs of MOSFETs/inductors in step, called phases. This is accomplished by modifying the triangle wave generator present inside every PWM control chip to output n waves each with a 360°/n phase shift, and add n lots of PWM control circuitry along with it. CPU voltage regulators often have 6 MOSFETs and 3 inductors near the socket - each of those pairs is switching on in accordance with a wave that is 120° out of phase with the other. This has the effect of

- reducing the load on one phase, as the current draw is now spread out over 2, 3 or even 4 phases

- reducing ripple voltage because the effective frequency at which the whole circuit switches has increased by a factor of 2, 3 or 4 - more frequent switching = less time for voltage to drop across the output capacitors

- reducing heat density of the controller - less current through each phase = heat dissipated over larger area = less onus on the PCB conducting it all away

- increases efficiency - MOSFETs are more efficient at lower frequencies because they have gate capacitances that must be charged and discharged before they turn on/off. To do so requires current from the drive circuit which wastes energy. Lower frequency = less charges/discharges and so less rate of energy loss. Also the inductors, which are magnetically-affected lengths of wire, have a DC resistance which dissipates heat according to Ohm's law - P=I²R. Less current per inductor and more inductors in parallel = less heat loss due to DC resistance.

It doesn't stop there. Gigabyte sometimes put an expansion slot for an additional power module to give "6-phase power" - what this actually does is daisy-chain another 3-phase regulator onto the one on the motherboard. A control signal is put to the module from the core voltage chip that synchronises the whole lot. This normally isn't necessary, with most manufacturers opting for 3-phase systems on most Athlon64 and Pentium4 (even Prescott-worthy) motherboards. Some 4-phase regulators are starting to hit the market though.

VID inputs are common on CPU VCORE regulators, as this allows the CPU to set it's own specific voltage (which can be overridden by the BIOS). In controller chips that have VID inputs the digital signals are converted into a variable reference voltage by means of a precision digital to analogue converter (DAC). The rest of the control circuitry is exactly the same as a non-VID chip, and volt modding these is carried out in the same fashion 99% of the time.

1.2 The conventional volt mod: feedback theory

Fortunately for us however complex the control chip, they almost always leave a simple potential divider with the job of taking the output voltage and feeding it back into the chip. The chip has an internal precisely-calibrated reference voltage that the error amplifier inside the chip compares the stepped-down output voltage to. If the voltage is too high, it reduces the duty cycle. Too low and it increases it. What a volt mod does is trick the chip into thinking the output voltage is too low and so boosts it.

The typical potential divider circuit is like this:

and the output voltage in DC terms can be expressed as a function of the two resistors and the reference voltage:

Now this means we can increase Vout by decreasing R2. This happens because the chip wants to keep the Vref voltage constant and equal to it's own internal reference voltage. Decreasing R2 = more voltage dropped across R1 and so Vout needs to be higher to keep Vref at whatever the internal voltage is. The equation for the voltage after the mod is thus:

What does this mean? Fortunately for us R2 is the resistor between the feedback pin of the IC and ground, so it is simple to fix a resistor permanently or semi-permanently to the board; just solder the resistor to the legs of the IC corresponding to ground and FB, or alternatively use a Surface Mount Grabber/Pomona Grabber to have a removable mod. Many people prefer the variable "how fast do you want to go today?" mod, or use jumpers between the resistor and IC leg to enable/disable the voltage boost.

1.3 The conventional volt mod - finding out what to mod

What pins are FB and Ground? And what if there is more than one voltage controller chip?! What's the voltage?!?!?!?!

To find out the FB and Ground pins you need the datasheet for your chip. There should be some numbers on the top of the chip, enter these into Google. If you have two numbers then one will be a serial number and the other a part number. One will yield results, the other will not. Enter the part number into Google and if you get a PDF link, follow it. The description should contain some or all of these key words:

Buck PWM Voltage Controller DC-DC

If you get "dual MOSFET" or something then the "chip" is actually two switching MOSFETs that the voltage controller drives. These are commonly used on low-power regulators instead of the larger "standard" 3-leg MOSFETs.

Some companies do not let Google crawl their site directly so you don't get Google hits for the PDF file, but they do release their datasheets to a database. A good one to use is www.doom.com which requires you to pay to view the sheets from the site, but will look up stuff for free. Enter the part number and find out who the manufacturer is from the results. Then go to the manufacturer's site to get the datasheet.

Since most volt mods are for video cards, here are some vid-card specific guidelines..

Many video cards do have more than one controller chip however, and you need to enter the part number of every little chip on the board with 8 pins or more. They shouldn't be too numerous, but check both sides of the card. I haven't seen a vid card yet that has the control circuitry on the underside as the large smoothing capacitors need to be mounted as close as possible to the switching circuit, so they are often put on the opposite side of the board as close as possible to the chip. Putting large caps on the top of the board is almost unheard of due to form factor specifications.

These multiple chips on a video card will control different voltages. Typically there are 3, VDDR, VDDQ and VGPU. You can only tell which is which by measuring the voltage across caps near the chip/MOSFETs. Put a voltmeter across the exposed capacitor leads (if you don't feel like frying your card, put heatshrink or a thin strip of duct tape on the test probe so that only a tiny bit of metal is exposed, to prevent accidents). Record all the voltages and what chip they are close to.

VGPU is most likely in the range of 1.2-1.8V, VDDR 2.5-2.8V, VDDQ is definitely going to be less than DDR, but can be very close to it. You measure the voltage at multiple points by putting a voltmeter across the large electrolytic capacitors with legs that stick through the board. Voltages are easy to find on video cards. Caps on the underside have their legs poking up through the PCB, so you can stick a multimeter on them to measure the voltages. Important voltages that have a lot of current draw typically have lots of electrolytic caps between it and ground.. If you have only surface-mount capacitors on your card, or if you are working on a motherboard then you will need to find an alternative place to measure if you have shaky hands. You can try an inductor leg that is the furthest away from the MOSFETs compared to ground, for example.

With my 9600XT I got these voltages when probing around with my multimeter.

http://premium.uploadit.org/L337M33P/Voltmodguide/9600XT-Voltages2.PNG

http://premium.uploadit.org/L337M33P/Voltmodguide/9600XT-Voltages.PNG

Voltage regulator chips on a motherboard are going to be trickier. There are many more chips on a motherboard, not all of them standard sizes either. Still, the same principle applies. Put all the part numbers in and see what comes out. Finding the CPU core voltage regulator should be easy, it's usually a large chip as it has a built-in 5- or 6-bit DAC to convert the CPU VID pin data to a voltage. Finding the DDR and chipset voltages and their respective controllers will be hard as the chips are often buried amongst other components. The legs of the caps are on the other side of the motherboard, so you need an alternative point to look for. Don't use MOSFET legs as they will typically have a) 0V b) a switching waveform (which you will ground through the capacitance in the multimeter) c) a voltage that is close to, but is not, the right voltage.

Here are some examples of what to look for:

VDD Chips on an A7N8X

VDDR chips on an A7N8X

The best place to look is the legs of inductors. The leg of the inductor on the side of the capacitors (the other side will be connected to one or two MOSFETs) should have the right voltage on it. If you have a pomona grabber or really small probe clip then it should easily fit around the leg.

1.4 The conventional volt mod - the tools

You will need (i.e. don't attempt a mod without):

Digital Volt Meter

Be sure to know how to use it properly. They are inexpensive, places like RadioShack sell them. You need crocodile clip ended test leads as well as the pointy types.

Variable Resistors

A selection of 10-turn or multiple turn high-precision potentiometers. You need values above 10K, but less than 100K. Most feedback (R2) resistors are in the range 100-200 ohms.

Pomona grabbers

The easiest way to clip a lead on to a surface mount chip. They have two little wire clips that come out when you press the button in and are spring-loaded.

Linky

Soldering kit

Soldering is the key to making a permanent and successful volt mod. If you aren't at least moderately competent with a soldering iron, don't break it out on a $200 video card. If you do know what you are doing, a medium-power iron is all you need for surface mount work, and the tip size is far more important. Use a 1mm point tip or less, and make sure it can be well tinned as you will find that applying solder wire will just create huge blobs on the joint. Tin the bit then use the small amount of solder to stick the chip leg and lead together. For soldering caps/resistors/other random chips to the PCB in pursuit of a mod, I find that a selection of fine tweezers, needles and cocktail sticks is ideal for nudging the tiny components into place.

Wire

If you are using a variable resistor then it's advisable to run a short length of wire (no more than 10cm) to enable you to mount the VR at the edge of the PCB/clear of surrounding components. Short lengths of wire are preferable because a long run can increase the risk of snagging it and ripping the wire off, and longer wires act as radio-frequency aerials capable of picking up more noise than they would if they were short. Solid core wire is the best to use since it allows accurate soldering without it going everywhere. Heatshrink-wrap the connections to the VR if you must.

Glue of the hot glue gun sort

Secure your volt mod. Glue the resistor body or the VR's plastic case to a bare bit of PCB. It allows easier access to the VR and prevents any solder connections from breaking off. If you keep the joint to the chip low-profile then you needn't worry about the leads being broken off.

1.5 The conventional volt mod - performing the mod

With the hardware off/computer off, measure the resistance between the feedback pin and ground. Put the -ve lead on the ground and +ve on FB to avoid reverse-biasing any circuitry inside the chip. The resistance should be under 1K and moderately steady. Therefore if the resistance is 1K putting a 1K resistor in parallel with it will halve the resistance and double the output voltage, which you don't want - you at most want a 20% increase. This is why you start with a high-value variable resistor and slowly lower it to get the desired hike in voltage. Then you unclip it and measure the resistance.

Adjust the resistor to max (max resistance between middle pin and an end pin) and solder two wires to these pins. Put the pomona grabbers on these wires.

Don't attach or remove the grabbers/leads while the piece of hardware is on! If you short out a leg then stuff will fry!

Using crocodile clips or similar, attach the voltmeter to the voltage measuring point, e.g. a capacitor that you know has the GPU voltage across it. Record the voltage. If you are doing a mod to a motherboard then you still need a voltage measurment point, NOT hardware monitoring. Only use hardware monitors to confirm your readings. Don't do a mod if you don't know where to stick the voltmeter!

Pin 1 is designated by a mark on the top of the chip - a dot or chamfer on the case, or if the top end has a dent in it or is entirely shaded then Pin 1 is the left hand pin closest to the shaded area, with the shaded area at the top.

CAREFULLY attach the grabbers to the FB and Ground pins. Power on. The voltage should go up from the previous voltage by a tiny fraction. If no change is detected wind the pot SLOWLY to lower the resistance. If no change happens by the first turn then you screwed up, power off and take the pomona grabbers off pronto. Recheck the datasheet, and if you were right then you may be altering another voltage. Check each of the different voltages that you got across the capacitors and put the grabbers back on with the pot set to full resistance again. If you still don't get a change then you are doing something wrong, ask in this forum for assistance.

If you don't get a decent boost in speed from the volt mod then take it off as it's doing no good to the chip. If it is successful then congratulations, and post how you did it!

1.6 Pencil Volt Modding

This is a cheap and dirty method of quickly increasing the voltage from most regulators - I would NOT recommend it for CPU voltage hikes as they are prone to being highly variable.

The basis of the pencil volt mod is that graphite is conductive. In fact 2B/4B pencils conduct more than hard ones because they have less clay in the leads. For pencil modding you want a 2B pencil. An additional current path is formed around one of the feedback resistors by simply drawing or scribbling a line along the side of it.

To find out what to mod, the method is nearly the same as the conventional mod except that you have to carry out one more step: find the feedback resistor that connects FB and ground. I suggest you try to follow the PCB tracks first, and if the suspected resistor has the same value of resistance as what you measured at FB/GND then it's the right one.

I HIGHLY recommend that you monitor the resistance change with a multimeter as you are pencilling the resistor. To lower the resistance just rub the pencil down the side of the resistor between the two solder caps. You should be able to get a modest reduction in resistance, of the order 10%. Use the "new voltage" formula to find out what the modded voltage will be from the new resistance between FB and GND. To reduce the resistance just stick a cotton bud in there and wipe it off. Do NOT let the pencil dust get under BGA chips or between pins. That is a Bad Thing™

I have performed this mod myself and know first-hand that it can produce very variable results. Breathing on the resistor increased the voltage due to the moisture on the graphite! Therefore I do not recommend that this be a permanent mod.

2.0 Current sensing - the roots of the droop mod

As most of the droop mods performed seem to be on the Asus P4C800/-e model, I will cover what is involved when you mod that particular board. More generally though, a droop mod does this:

Inside most modern CPU Vcore regulators there is an additional feedback loop that modifies the output waveform depending on the load placed upon the system. This method of control uses current sensing and can provide several useful features in only one additional feedback loop.

Current sensing can be achieved one of three ways

- Putting a known value of resistance in the output current path and measuring the voltage drop across it, which changes in accordance with V=IR. This method is rarely used in CPU Vcore regulators because the resistance would have to be incredibly low to avoid dissipating large amounts of heat.

- Measuring the voltage drop across the upper MOSFET when it is fully ON and averaging it over time

MOSFETs have discrete resistances when they are fully on. This resistance does change with the voltage across the source and drain somewhat, but with a fixed supply voltage and fixed output voltage this can be considered nearly constant. - Measuring the voltage drop across the output inductor

Inductors are lengths of wire coiled around magnetic material and as such have a DC resistance. This is an unwanted variable and so the manufacturers try to make it as small as possible, but the small resistance of 80 milliohms or so is constant and if the voltage drop is averaged over sufficient time then the current flowing through the inductor can be measured.

Current sensing is useful because it allows a droop function (or "Active Voltage Positioning") to be implemented along with load balancing (putting more current through one meatier phase or making sure the currents are equal in all) and allows for overcurrent protection methods.

The droop function means that the output voltage drops linearly with load, reducing the effect that transient current surges have on the output voltage and allowing the manufacturer to use fewer capacitors. This datasheet excerpt puts it across quite well:

http://www.intersil.com/data/an/an9672.pdf said:The HIP6004EVAL1 uses a droop function to maintain output voltage regulation through load transients with fewer (or less costly) output capacitors. With a high di/dt load transient typical of the Pentium-Pro microprocessor, the largest deviation of the output voltage is at the leading edge of the transient. The droop function adds a deviation as a function of load that counters the transient deviation. Figure 9 illustrates the static-load droop characteristic. With no-load, the output voltage is above the nominal output level. The output decreases (or droops) as the load increases.

With a dynamic load, the droop function pre-biases the output voltage to minimize the total deviation. Prior to the application of load, the output voltage is above the nominal level and the transient deviation results in an output lower than the nominal level. Figure 6 illustrates the droop function performance on the HIP6004EVAL1 converter. The transient deviation is approximately 130mV. At light load, the output voltage is about 50mV higher than the nominal output voltage of 2.8V. At full load, the output voltage is about 40mV lower than nominal. The total deviation is within ±80mV with the droop function compared to a deviation of over ±130mV without this function. Since the voltage excursions at the transient edges are mainly a function of the output capacitors, the converter uses fewer capacitors.

Performing a droop mod on a Vcore regulator often involves soldering another resistor to the circuit lowering the gain of the current summing amplifier. It most likely will be different for different converters so it is essential that you find the datasheet, know how it works and know what a ballpark resistance should be before attempting a mod.

2.1 The P4C800 droop mod

The droop mod for the P4C800 serves to reduce the Vcore voltage drop under load. Asus have left off several capacitors and the secondary low-side MOSFET for each phase and as a result increased the droop strength to compensate for their cost-cutting. This, while fine in principle, does not sit well with overclocking which increases the current draw beyond that of what is normal, and consequently the output voltage droops too much resulting in an unacceptable difference between idle and load.

The control chip used is the ADP3180 from Analog Devices. It has 3 functions derived from sensing the current in the inductors - overcurrent protection, droop function and current load balancing. The one we are interested in is the summing amplifier that is connected across each of the inductors.

On page 13 there is a diagram of the droop circuitry, CSSUM and CSCOMP etc. These pins and the surrounding resistors form an inverting summing amplifier that measures the average current being drawn by the processor using the inductors' DC resistances. The voltage drop is averaged because of that phat capacitor and associated resistor forming an RC network that reduces the gain of the system at high frequencies.

What happens when you droop mod it is you solder a resistor (28K) directly in parallel with the cap. This decreases the gain of the circuit (and increases the rolloff frequency, an added bonus as the circuit responds quicker) and thus from equation (6) the "DC resistance" of the whole converter is less. This makes the voltage slope (VCORE versus Iout) less so there is LESS voltage difference between idle and load, and less droop under heavy load. This will compromise the output ripple voltage slightly when a high-current transient is put on the circuit, but it is still within normal parameters.

The droop function was also designed to allow the incorporation of a temperature-sensing thermistor in the circuit. This was to allow the circuit to respond to the change in resistance of the inductors with temperature - copper increases in resistance with increasing temperature so if a thermistor is put close to the inductor then the circuit can be further compensated to adjust the droop with temperature. For most purposes a simple reduction in droop is sufficient.

3.0 Overcurrent protection mods

Undertaken by the more extreme overclockers, an overcurrent protection mod increases the current limit threshold of the controller. When a core voltage controller experiences a heavy current draw it can trip and operate in "hiccup" mode. In this mode it essentially turns off and occasionally tries to turn the output voltage back on to test if the overcurrent condition is still present. This prevents damage to the MOSFETs and PCB in case of a short. When doing some nuclear-powered overclocking and volt modding, past a certain increase in clock speed or core voltage may cause the whole thing to crash unexpectedly or give a blank screen. This is the overcurrent kicking in and turning off the core voltage, with obvious consequences.

Overcurrent protection is accomplished mostly 2 ways. As core voltage controllers rarely use the series current sense resistor anymore, the voltage drop across the upper MOSFET is most often used for things like graphics cards, and the current in the inductor is used in things like the ADP3180. In the case of the MOSFET-sensing chip, there is a resistor between the supply voltage and a pin, which acts as a fixed current sink. This creates a constant voltage drop according to V=IR, and this dropped voltage is compared to the drop across the MOSFET when the MOSFET is switched on. This result is then averaged and fed into a comparator. If the voltage drop across the MOSFET becomes greater than the drop across the resistor then the circuit triggers the hiccup-mode operation.

It follows that increasing the resistance between the current sink pin and the supply voltage increases the drop across the resistor and thus increases the threshold voltage drop across the MOSFET. This in turn can allow more current to pass without tripping the overcurrent protection.

With the inductor-sense method and multiple phases it can be much more difficult to do it successfully unless there is a dedicated pin and current limit setting resistor.

A mod with the MOSFET method is simple - desolder the resistor and replace it with a higher value. Alternatively you could connect a 1K pot to one of the resistor's ends and solder it back on, so you can't go below the standard overcurrent protection, only increase it.

These mods require a little more forethought and understanding than your average volt mod, and you need to do the following diagnostics before attempting one:

- Find the datasheet for the chip and read it. Make sure that any overcurrent protection circuitry is SEPARATE from the carefully-compensated feedback loop. By separate I mean a resistor on it's own with the sole purpose of setting the current limit. Modding an odd-looking circuit with a non-separate overcurrent function could destabilise the whole thing.

- Verify your analysis of the datasheet with experimental data - measure where said resistance is meant to be. It should be a stable figure not far different from the value specified in the datasheet

4.0 VTT, VREF and other weird voltages

DDR SDRAM is a memory technology used on almost all host CPU and many mid and low-end graphics cards. It is a requirement of the DDR signalling interface, SSTL-2 (Stub Series Termination Logic) to have a bus termination voltage, VTT, and an internal reference voltage, VREF.

VTT

Data buses are terminated at the ends by a resistor connected to another voltage, usually ½ the signal amplitude voltage. This serves the purpose of preventing signal “reflections" which would otherwise happen if the data/address wires just stopped at the end of the run. I can't be bothered to come up with an analogy so here’s one courtesy of Google:

http://www.pcguide.com/ref/hdd/if/scsi/cablesTermination-c.html said:You can do an experiment (either physically or mentally) to illustrate why termination is required on a SCSI[or DDR] bus. Hold one end of a piece of rope about six feet long and have someone else hold the other end. Stretch the string so it is reasonably taut, but not tight, and then snap down on one end sharply. You will form a wave that travels down the string. When it reaches the end of the string it will "reflect" off the end and travel back again toward you, and then reflect again. It will go back and forth across the string, decreasing in amplitude each time until it eventually dies out.

Electrical signals travel across wires in much the same way as physical waves travel across a string. When they reach the end of the wire, they will reflect and travel back across the wire. The problem is that if this is allowed to happen, the reflected signals will interfere with the "real" data on the bus and cause signal loss and data corruption. To ensure that this does not happen, each end of the SCSI bus is terminated. Special components are used that make the bus appear electrically as if it is infinite in length. Any signals sent along the bus appear to go to all devices and then disappear, with no reflections.

For more back-story and JEDEC specifications see this application note.

Each signal wire is run to a resistor and the other end of the resistor connects to the common VTT rail.

A passive termination would just mean that the resistor of similar resistance to the trace gets connected to ground, but all motherboards and graphics cards employ active termination. Active termination means that a) there is a termination voltage and b) this voltage is regulated.

It is a requirement of the regulator to be able to both source and sink current to keep VTT at a fixed value. These regulators can be switched or linear, and the choice is usually down to how many chips are going to be hanging off the bus/how fast it goes. Switched regulators can typically source and sink much more current than linear ones, but are complicated and more costly, so linear ones are most often used.

Examples:

My 9600XT’s bus termination regulator and datasheet

Abit NF7-S termination regulator datasheet

As you can see from the datasheet of the motherboard termination regulator several features have been lumped into one chip. Primarily the ACPI suspend-to-RAM feature needs to be supported by the various memory voltage regulators, and this needs a connection to +5VSB as well as the chipset to work. Other features like Power_GOOD outputs and digital voltage increase pins are often implemented.

A word on VREF

VREF is another voltage supplied to the memory chips in addition to VDDQ and VDDR. It is meant to be ½ of VDDQ to within a few percent, and serves to provide a reference (surprise surprise) to the receiving circuitry. If the voltage on the bus is > VREF then a “1” is passed to the internal circuitry, if it is < VREF then a “0" is passed along. While this may sound trivial and unecessary consider that the DDR bus is operating at 200+MHz with about 2.5V signal swing. Any small amount of high-frequency noise such as caused by another data bus nearby will cause jitters and noise in the adjacent bus. Adding a reference voltage means you can use comparators to clean out the garbage.

For more information, diagrams of the equivalent circuits and notes on the SSTL-2 interface see this PowerPoint presentation. It even has oscilloscope graphs of the DDR bus voltages.

As the voltage references on such chips are rarely the result of a potential divider this can cause problems if you bump up VDDR by volt-modding the VDDR controller – the VTT regulator chip still thinks that the voltage is at a set 2.7 or 2.6V and fails to increase VTT to compensate.

4.1 VTT, VREF and VTT=VREF mods

As touched on above, a VREF or VTT mod serves to increase stability rather than increase performance. As specified on most DDR SDRAM product datasheets, VREF and VTT should fall within a very narrow margin centred on 1/2 of VDDQ.

E.g. from Samsung's popular graphics card RAM datasheet:

(Page 10, DC operating conditions)

VREF

Min: 0.49*VDDQ

Max: 0.51*VDDQ

VTT

Min: VREF-0.04V

Max: VREF+0.04V

As you can see these are narrow operating regions, so when overclocking having a precisely-tuned VREF and VTT setup can increase your overclocking headroom. Normally the RAM voltage controllers will output a reference and termination voltage that is exactly half of VDDQ, but when you start doing VDIMM volt mods and VDDQ volt mods the VREF and VTT voltages can start to go out of whack. This seldom occurs on boards where you just mod VDIMM because VDDQ is (mostly) independent, but when you are going for flat-out speed with a DIMM voltage in excess of 3.3V and the whole entourage of mods, a correction to VREF and VTT may be necessary.

Most VREF/VTT chips employ direct feedback, which means that there are no potential dividers we can stick a resistor across to alter the voltage. For mods to boards such as the IC7-G and NF7-S you are in effect replacing the wire with a small-value potential divider which you CAN adjust. The reason values much smaller than the ordinary volt mods is because the chip may take a small current when measuring VTT/VREF and this will affect the voltage produced by the potential divider because it relies on very little current being drawn off it with respect to the current flowing through it.

These mods often require putting a resistor in the current path from the voltage rail to the chip, so this is why you have to cut traces on the motherboard. You bypass the cut with the resistor you solder to the board.

For tracking circuits, this essentially produces a voltage boost to the feedback when Vdimm goes above a certain value. This kicks the chip up the rear end and makes it output a higher voltage than it would normally if you just increased Vdimm. The circuits are usually specific to each motherboard due to variations in current, gain and severity of VTT tracking loss.

5.0 Capacitor Mods

Capacitor modding, or more usually abbreviated to capmodding, is the process of adding or otherwise altering the bulk decoupling capacitors on motherboards/graphics cards. The usual cap mod on a graphics card is to add extra capacitors in parallel with the ones already there but on the topside of the board. For motherboards it's a little more complicated as sticking them on the back means you have to cut motherboard trays and such.

The aim of the mod is to reduce the ripple voltage that the switching regulator produces. As the inductor and capacitors are driven by a PWM waveform you will get some small ripple voltage due to the change in current in the inductor. Most switching regulators used on motherboards are synchronous and operate in the continuous mode (i.e. the inductor current never drops to zero) which reduces ripple somewhat, but doesn't eliminate it. Typical values are 50mV peak to peak.

Sticking extra capacitors on increases the charge storage capacity of the whole converter for a given voltage. Translated that means more charge can be drained from the capacitors for the same level of voltage drop, or conversely less voltage drop for a given transfer of charge. This is A Good Thing™, since when pushing the envelope on phase-change cooling you are going to be drawing some hefty amperes and need more storage capacity to compensate.

Another side-effect of adding more capacitors is that it reduces the ESR of the bulk decoupling circuit - capacitors aren't perfect and have an equivalent series resistance that can be measured by how much current the capacitor can dump at any one time. Think of it as a bucket with a hose attached to a hole in the bottom. How fast you can get the water out depends on the width of the pipe and the level of water in the bucket. The constant of proportionality is the ESR.

ESR behaves like any normal resistance and so sticking capacitors in parallel reduces the overall ESR according to the parallel resistors rule. This increases the transient current availability of the converter (such as when you suddenly hammer the CPU with Prime95) and reduces the dip in voltage that happens at the instant of increased current.

While this may all sound like a perfect solution to juddery rails there are several caveats:

Adding different brands and ratings of capacitors means that the ESR is no longer constant per capacitor. The switching regulator has a carefully calculated zero in it's frequency response at the self-resonant frequency of the inductor-capacitor-ESR circuit and a pole at the break frequency of the ESR-C pair, to avoid oscillation. These are given by

Source

I would only recommend adding the same type of capacitor in parallel with the ones already in place because if C and ESR is kept constant for each capacitor, the second equation is unchanged, and FLC decreases, which has negligible impact up to a point.

This is my extrapolation of what to expect from cap modding, so I give it a massive health and safety warning, but other people have had a number of successes with any old capacitors that have a high enough voltage rating and approximately the right capacitance. Ideally you want to be looking at the supply voltage with an oscilloscope before sticking extra bulk capacitors on though.

Article source text: http://premium1.uploadit.org/L337M33P/Voltmodguide/VoltModGuide.txt

© 2005. NO rights reserved.

Last edited: